The Mechanical engineering, is plays a important role in today's Technology that Assist you to done things with ease, so let's learn about Concept of brakes Factor of safety - definitions, formulas, importance and factors affecting that helps to modernize our society.

So keeping these things in mind, Lets learn about the topic of Factor of safety - definitions, formulas, importance and factors affecting.

What is factor of safety ?

While designing a components or any objects, it is necessary to providing sufficient reserve strength in case of an accident.

This is achieved by considering a suitable factor of safety (FOS).

The factor of safety (FOS) is also called as safe factor (SF).

In simple word the factor of safety is a load carrying capacity of a system upto which load is sustained.

Factor of safety shows how much system is stronger than the required.

The factor of safety (FOS) is backbone of the entire structures and also of the safety equipments that are originates with engineers.

In the planning condition of all structures and safety equipments.

The engineers determine required overloading from the any object to remaining safe at the time of an emergency. Or at the time of accident cases.

Definitions and formulas of factor of safety:-

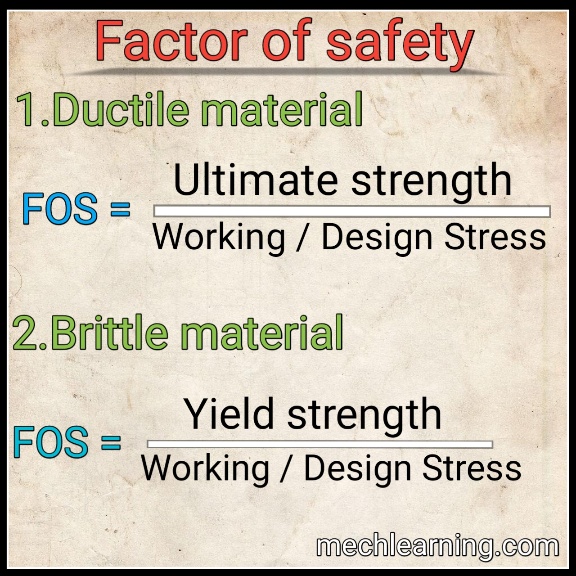

The factor of safety is defined as the ratio of ultimate stress (maximum) of an object or yield stress of an object to the working stress or a design stress. Is called as factor of safety (FOS).

Factor of safety is also defined as failure stress or failure load to the the working stress for working load.

The factor of safety is different for ductile materials and brittle materials.

The allowable stress is the stress value at which is used in a design to determine the dimensions of the components.

The allowable stress is the stress at which the designer expect will not be exceeding under normal conditions.

Factor of safety for various materials:-

1. For ductile materials:-

The factor of safety for ductile material is defined as the ratio of ultimate stress or maximum stress to the the allowable stress or working stress.

Examples:- ductile materials are steel, gold, copper, aluminum etc.

2. For brittle materials:-

The factor of safety for brittle material is defined as the ratio of of yield stress to the allowable stress or working stress.

Examples:- brittle materials are cast iron, glass, concrete etc.

Importance of factor of safety:-

The factor of safety is most important while designing of any components. Factor of safety considering the safety of the design under certain conditions.

factor of safety that increases the safety of peoples and also reduces the risk of failure of a components.

When it comes to safety equipments and also protection, the factor of safety is extremely important. If a structure fails there is a risk of injuries and countless deaths as well as financial loss.

The safety factor is higher when there is a possibility that a failure that will result in these things.

Higher the factor of safety that indication of high chance of safety and low risk.

The factor of safety insurance against the uncertainties and variety of unknown conditions.

Factors affecting on factor of safety:-

The magnitude of the factor of safety depending on the following factors:-

- Effect of failure

- Material of components

- Type of loads

- Degree of accuracy in forces

- Reliability of machine elements

- Cost of elements

- Quality of manufacturing

- Testing of machine elements.

1. Effect of failure:-

Sometimes the value of a machine element that involves alita inconvenience or loss of time.

Example:- failure of the valve in pressure vessel.

The factor of safety is high in applications where the value of a machine part that receives a serious accidents.

2. Material of components:-

When the component is manufactured by the homogeneous ductile material like steel the yield strength is important that time the factor of safety is usually small.

While considering a cast iron a component has non homogeneous structure that gives higher factor of safety.

3. Types of load:-

The factor of safety is minimum when the external force acting on the work piece is static.

The value of factor of safety is higher selected when the machine element is subjected to impact loading.

And due to the impact load factor usually having higher factor of safety.

4. Degree of accuracy in Forces:-

The force acting on the machine element are calculated at low factor of safety and a machine component subjected to force whose magnitude and direction is uncertain and unpredictable that considering higher factor of safety.

5. Reliability of machine elements:-

In certain applications like the continuous process equipments power station high reliability of component is used for the factor of safety is high with increasing reliability.

6. Cost of elements:-

As the factor of safety increases the dimensions of the components and the requirement of the material is increases due to that the cost of the component is increased with increasing factor of safety.

7. Quality of manufacturing:-

When a quality of manufacturing is high varieties in dimensions of a machine elements are less factor of safety is considered but at the higher factor of safety the components required good manufacturing quality.

8. Testing of machine elements:-

A low factor of safety that can choose when the machine components can be tested under actual condition.

The high factor of safety is necessary when it is not possible to testing a machine part where there is a deviation between test condition and actual service conditions.

Here we concluding, If you have any queries about the Factor of safety - definitions, formulas, importance and factors affecting then feel free to comment below.

Related articles:

i calculated FOS of hanging book shelf, its FOS is coming "9"....why?

ReplyDelete