The Mechanical engineering, is plays a important role in the today's Technology that help you to done things with easily, so let's learn about Concept of Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications which helps to modernize our overall society.

So keeping these things in mind, Lets learn about the topic of Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications.

Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications

Introduction of Single plate clutch :

A single plate clutch

is a type of clutch mechanism that is used in vehicles for transmitting power

from the engine to the transmission.

It consists of a single clutch plate that

is sandwiched between the flywheel and the pressure plate, which is actuated by

a mechanical linkage, hydraulic system, or cable.

Single plate clutches are

commonly used in small cars, motorcycles, and light-duty commercial vehicles

due to their simple design, low cost, and lightweight.

In this article, we will

take a closer look at the diagram, construction, parts, working, advantages,

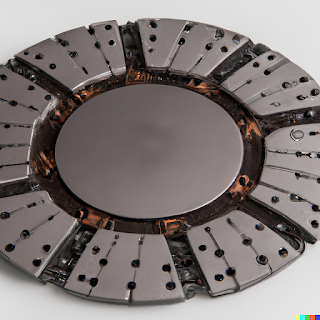

disadvantages, and applications of the single plate clutch.Diagram:

The basic components of a single plate clutch

are the flywheel, clutch plate, pressure plate, and release bearing. The

flywheel is mounted on the crankshaft of the engine and rotates along with it.

The pressure plate is connected to the clutch release mechanism and is

responsible for applying pressure to the clutch plate. The clutch plate is

sandwiched between the flywheel and the pressure plate and is free to rotate

with the flywheel when the clutch is disengaged.

The release bearing is used to

separate the pressure plate from the clutch plate, allowing the clutch to

disengage.

Construction:

A single plate clutch is a simple mechanism that

consists of a clutch plate, pressure plate, flywheel, and release bearing. The

clutch plate is made of a friction material and is positioned between the

flywheel and the pressure plate.

The pressure plate is responsible for applying

pressure to the clutch plate and is connected to the clutch release mechanism.

The flywheel is mounted on the crankshaft and rotates with the engine. The

release bearing is used to separate the pressure plate from the clutch plate

and is typically actuated by the clutch pedal.

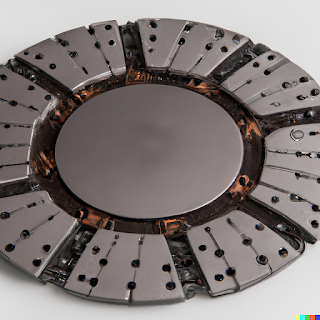

Parts:

Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications

The main components of a single plate clutch

are:

Clutch Plate: This is the component that

transmits torque from the engine to the transmission. It is made of a friction

material, such as asbestos or ceramics, that provides the necessary friction

for torque transfer.

Pressure Plate: This component applies pressure

to the clutch plate to engage the clutch. It is typically made of metal and is

mounted to the flywheel.

Flywheel: This component is mounted on the

crankshaft and rotates with the engine. It provides a smooth surface for the

clutch plate to ride on and helps stabilize the engine.

Release Bearing: This component is used to

disengage the clutch by separating the pressure plate from the clutch plate. It

is mounted on a lever or shaft that is actuated by the clutch pedal.

Working:

A single plate clutch works by using the

pressure plate to apply pressure to the clutch plate, which in turn transmits

torque from the engine to the transmission. When the clutch pedal is depressed,

the release bearing separates the pressure plate from the clutch plate, causing

the clutch to disengage. This allows the engine to run independently of the

transmission, allowing the driver to shift gears without interrupting power

transfer.

When the clutch pedal is released, the pressure plate returns to its

normal position, re-engaging the clutch and transmitting torque from the engine

to the transmission.

Advantages:

Simple design: The single plate clutch is simple

in design and easy to understand, making it a cost-effective solution for many

vehicles.

Lightweight: Single plate clutches are

lightweight, which helps to reduce the weight of the vehicle and improve its

performance.

Smooth engagement: The single plate clutch

provides smooth engagement, which results in a smooth and comfortable driving

experience.

Disadvantages:

Limited Torque Capacity: Single plate clutches

have limited torque capacity and may not be suitable for high-performance

vehicles or applications that require high torque.

Wear and Tear: Over time, the friction material

on the clutch plate may wear out, reducing its effectiveness and requiring

replacement.

Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications

Applications:

Single plate clutches are commonly used in small

cars, motorcycles, and light-duty commercial vehicles. They are also used in

high-performance applications where the limited torque capacity is not an

issue.

Here we concluding, If you have any queries about this topic of Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications then feel free to comment below.

To want check extra articles, please visit on the link www.mechlearning.com

Related articles:

|

| Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications |

Diagram:

The basic components of a single plate clutch are the flywheel, clutch plate, pressure plate, and release bearing. The flywheel is mounted on the crankshaft of the engine and rotates along with it.

The clutch plate is sandwiched between the flywheel and the pressure plate and is free to rotate with the flywheel when the clutch is disengaged.

Construction:

A single plate clutch is a simple mechanism that consists of a clutch plate, pressure plate, flywheel, and release bearing. The clutch plate is made of a friction material and is positioned between the flywheel and the pressure plate.

The pressure plate is responsible for applying pressure to the clutch plate and is connected to the clutch release mechanism.

The flywheel is mounted on the crankshaft and rotates with the engine. The

release bearing is used to separate the pressure plate from the clutch plate

and is typically actuated by the clutch pedal.

Parts:

|

| Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications |

The main components of a single plate clutch are:

Clutch Plate: This is the component that transmits torque from the engine to the transmission. It is made of a friction material, such as asbestos or ceramics, that provides the necessary friction for torque transfer.

Pressure Plate: This component applies pressure

to the clutch plate to engage the clutch. It is typically made of metal and is

mounted to the flywheel.

Flywheel: This component is mounted on the

crankshaft and rotates with the engine. It provides a smooth surface for the

clutch plate to ride on and helps stabilize the engine.

Release Bearing: This component is used to

disengage the clutch by separating the pressure plate from the clutch plate. It

is mounted on a lever or shaft that is actuated by the clutch pedal.

Working:

A single plate clutch works by using the pressure plate to apply pressure to the clutch plate, which in turn transmits torque from the engine to the transmission.When the clutch pedal is depressed, the release bearing separates the pressure plate from the clutch plate, causing the clutch to disengage. This allows the engine to run independently of the transmission, allowing the driver to shift gears without interrupting power transfer.

When the clutch pedal is released, the pressure plate returns to its

normal position, re-engaging the clutch and transmitting torque from the engine

to the transmission.

Advantages:

Simple design: The single plate clutch is simple in design and easy to understand, making it a cost-effective solution for many vehicles.Lightweight: Single plate clutches are lightweight, which helps to reduce the weight of the vehicle and improve its performance.

Smooth engagement: The single plate clutch provides smooth engagement, which results in a smooth and comfortable driving experience.

Disadvantages:

Limited Torque Capacity: Single plate clutches have limited torque capacity and may not be suitable for high-performance vehicles or applications that require high torque.Wear and Tear: Over time, the friction material on the clutch plate may wear out, reducing its effectiveness and requiring replacement.

|

| Single plate clutch - diagram, construction, parts, working, advantages and disadvantages, applications |

Applications:

Single plate clutches are commonly used in small cars, motorcycles, and light-duty commercial vehicles. They are also used in high-performance applications where the limited torque capacity is not an issue.To want check extra articles, please visit on the link www.mechlearning.com

0 comments:

If you have any doubt, please let me know